A manual lathe machine is a powerful tool used for shaping materials like wood, metal, and plastic. If you’re new to using a manual lathe machine, it might feel intimidating at first. But once you understand how to operate it safely and efficiently, you’ll see how versatile and effective this machine can be. In this blog, we’ll guide you through the best practices for beginners using a manual lathe machine, from understanding the basics to achieving precision in your work.

Understanding the Basics of a Manual Lathe Machine

Before diving into the details of using a manual lathe machine, it’s important to grasp its fundamental working principles. A manual lathe machine rotates the material (often called the workpiece) while a cutting tool shapes it. The operator controls the machine manually, guiding the cutting tool along the workpiece to create the desired shape. This machine is widely used in metalworking, woodworking, and even in some plastic crafting.

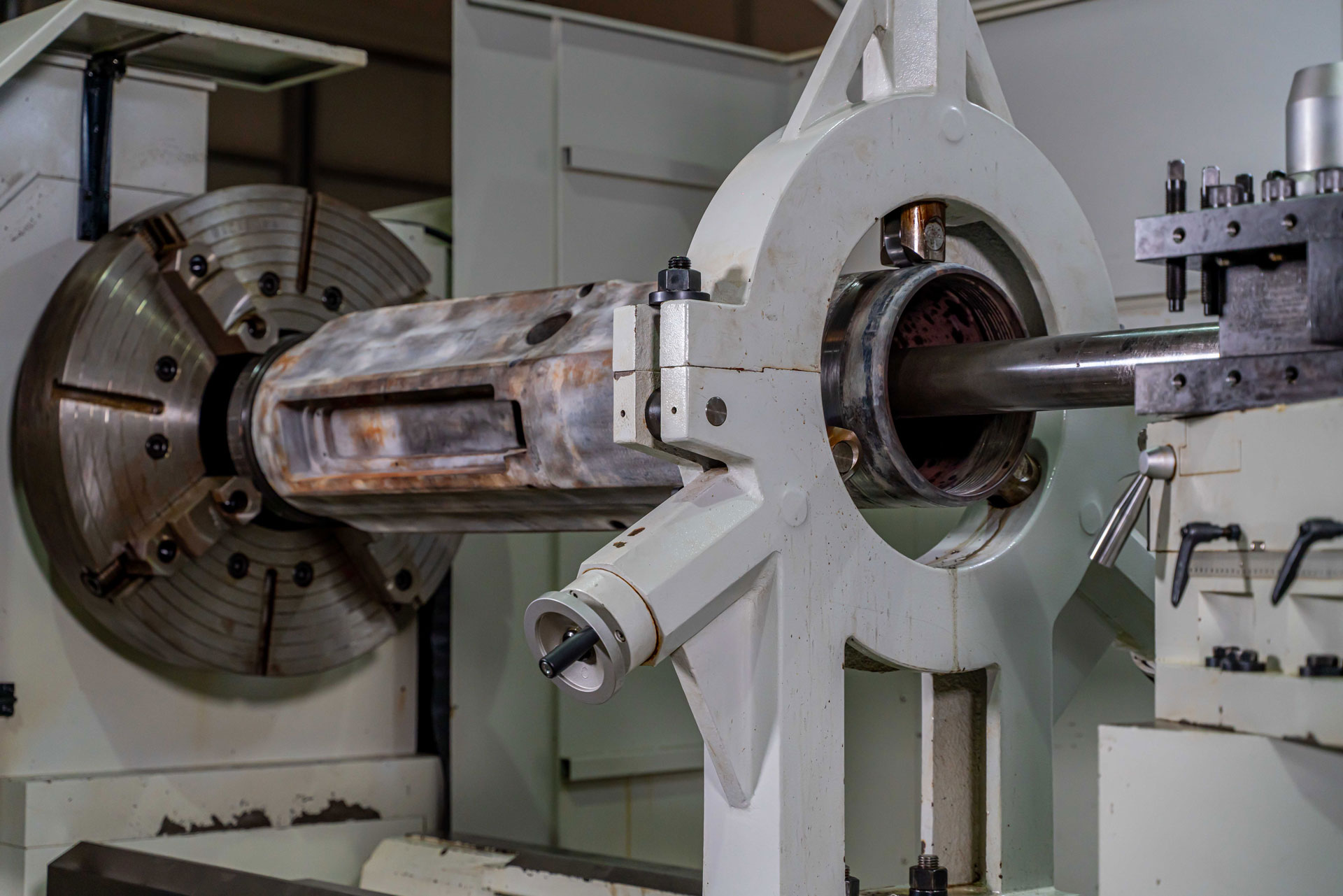

One of the key parts of a manual lathe is the chuck, which holds the workpiece in place. As the machine turns the workpiece, the cutting tool gradually removes material. Beginners often find that working with a manual lathe helps them develop a deep understanding of how different materials react to machining processes. Whether you are cutting, sanding, knurling, or drilling, the manual lathe provides the flexibility and control needed to create precise designs.

Getting Familiar with Lathe Machine Parts and Their Functions

Understanding the different parts of a manual lathe machine is crucial for operating it efficiently and safely. Let’s go over some of the most important components and what they do.

- The Bed: This is the foundation of the lathe. All the other parts are mounted on the bed, and it provides the necessary support for the workpiece and the tool.

- The Headstock: This part holds the spindle and motor. The spindle is responsible for rotating the workpiece, while the motor powers the lathe.

- The Tailstock: On the opposite end of the headstock, the tailstock supports the workpiece. It can also hold tools like drills, adding functionality to the lathe.

- The Carriage: This part moves the cutting tool along the workpiece. It can be moved manually or automatically, depending on the operation.

- The Tool Post: This is where the cutting tool is mounted. You can adjust the position and angle of the tool using the tool post.

Getting familiar with these parts and their functions helps you understand how the machine works as a whole. As a beginner, you should spend time learning how to adjust these components for different types of work. The better you understand the machine, the more control you’ll have over your projects.

Note – Unlock the full potential of precision machining with a high-quality manual lathe machine from Raysun. Whether you’re working with wood, metal, or plastic, achieve professional results every time. Explore more at Raysun today!

Safety Precautions When Using a Manual Lathe Machine

Safety should always be your number one priority when using a manual lathe machine. While lathes are powerful tools, they can be dangerous if not used properly. Here are some essential safety precautions every beginner should follow.

First, always wear appropriate protective gear. This includes safety glasses to protect your eyes from flying debris, and hearing protection if you’ll be working in a noisy environment. Loose clothing, jewelry, or long hair can easily get caught in the rotating parts of the machine, so make sure everything is secure before starting.

Next, make sure the workpiece is properly secured in the chuck. A poorly mounted workpiece can become a dangerous projectile if it comes loose while the lathe is spinning. Double-check that everything is tight before you turn on the machine. It’s also important to never leave the lathe running unattended. Always turn off the machine when making adjustments or when you’re finished with your work.

Finally, always be aware of your hands’ position relative to the cutting tool. A manual lathe machine operates with a lot of force, so keeping your hands clear of moving parts is critical. With these safety measures in place, you can focus on your work and develop your skills with confidence.

Tips for Operating a Manual Lathe Machine Effectively

Now that you understand the basics and safety precautions, let’s dive into how to operate a manual lathe machine effectively. As a beginner, one of the best practices is to start with smaller, simpler projects. This allows you to get a feel for the machine without the added pressure of creating complex designs.

A common mistake beginners make is cutting too much material at once. It’s always better to take small, gradual cuts. Removing too much material at once can cause excessive wear on the tool and reduce the accuracy of your work. Taking it slow not only improves the quality of your cuts but also extends the life of your tools.

Another important tip is to regularly check the alignment of your cutting tool. The tool should always be properly aligned with the workpiece to achieve the best results. An off-center tool can create uneven surfaces and reduce the precision of your work. Take the time to make sure everything is lined up correctly before starting.

Finally, keep the machine well-maintained. This includes lubricating moving parts and checking the condition of the cutting tools regularly. A well-maintained machine not only operates more smoothly but also produces more accurate results.

Key Benefits of Using a Manual Lathe Machine

Manual lathe machines offer several advantages, especially for beginners. One of the most significant benefits is the hands-on experience it provides. When you operate a manual lathe, you’re in full control of every aspect of the process. This helps you develop a deeper understanding of the material you’re working with and the tools you’re using.

Another key benefit is versatility. Manual lathes can handle a wide range of materials, from wood to metal to plastic. Whether you’re creating intricate designs or making simple repairs, the manual lathe offers the flexibility to handle almost any task. This makes it a valuable tool in both professional workshops and DIY projects.

Precision is another benefit of using a manual lathe machine. With careful operation and the right settings, you can achieve highly detailed and accurate results. While CNC machines are often praised for their precision, manual lathes allow skilled operators to create equally impressive work, especially when the operator has a keen eye for detail.

Common Mistakes Beginners Should Avoid

When learning to use a manual lathe machine, it’s easy to make mistakes. Understanding these common pitfalls can help you avoid frustration and improve your skills more quickly. One of the most common mistakes is rushing the process. It’s important to remember that working with a lathe takes time and patience. Trying to work too quickly can result in poor-quality cuts or even damage to the machine.

Another mistake is using dull or improper cutting tools. Always make sure your tools are sharp and suitable for the material you’re working with. Using the wrong tool can lead to rough cuts and reduce the accuracy of your work. It’s also important to understand the feed rate and speed settings for different materials. Beginners sometimes set the speed too high, which can cause the material to heat up and warp.

Finally, not cleaning the machine regularly is a common error. A dirty machine can affect performance and precision. Make it a habit to clean the machine after each use and remove any debris or chips that might have accumulated. Regular maintenance keeps your lathe in good working order and helps you achieve better results.

Conclusion

Using a manual lathe machine as a beginner may seem challenging at first, but by following these best practices, you’ll quickly gain confidence and improve your skills. Remember to start with the basics, prioritize safety, and take your time with each project. With practice and patience, you’ll be able to create precise, professional-quality work with your manual lathe machine. Whether you’re working with wood, metal, or plastic, the manual lathe is a versatile tool that will serve you well in a variety of applications.

For more insightful articles related to this topic, feel free to visit virtualnewsfit.com