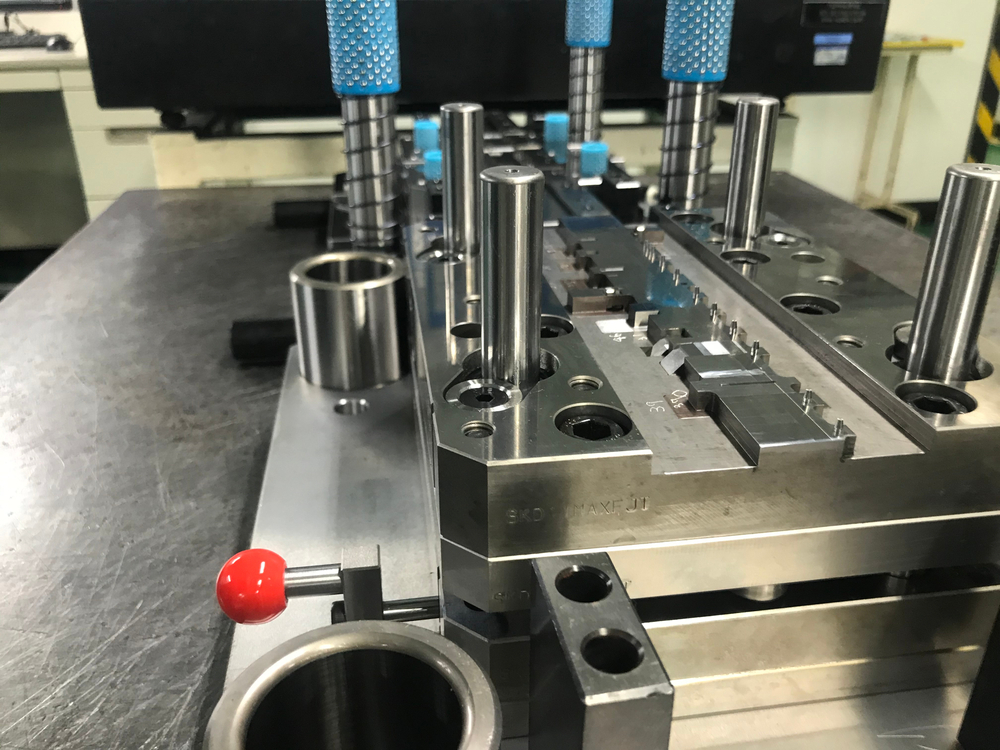

Stamping is a cold process that uses stamping presses and dies to make different shapes out of sheet metals. Flat sheet metals, also known as blanks, are an integral part of industrial engineering. These blanks enter the metal stamping machines that use die and tools to form metals into new shapes. Metal fabricators and production facilities place the metal sheet between dying sections, where pressure transforms it into the desired shape. Here is a complete guide to describe the automated stamping process.

Processes and Techniques

Automated metal stamping is a high-speed, low-cost manufacturing process that produces identical metal components in high volumes. These operations are appropriate for long and short production runs and compatible with other metal-related functions like punching, coining, blanking, embossing, flanging, and bending. Precision metal stamping machines do more to metal sheets than stamping. They also punch, cast, shape, and cut metal sheets.

Automated machines programmed with CNC offer high precision repeatability for every piece. Computer-aided design (CAD) and electrical discharge machining (EDM) programs ensure precision and accuracy. These progressive tools can create several pieces from one simultaneously.

Types of Metal Stamping Operations

These are a few types of metal stamping operations:

- Progressive Stamping: It involves using a series of stamping stations where a metal coil enters the press, moves with it horizontally, and finally transforms into the required item. This process is perfect for long runs because of its high repeatability and lesser damage. Each step in the process conducts a different bend, cut or punch, thus making the desired product shape up.

- Transfer Die Stamping: Similar to the progressive stamping process, the difference is that instead of running through the same machine, the metal piece moves on to the next station through a conveyor belt or another mechanical transport. It is a suitable process for bigger automotive parts that go through various phases.

- Four-Slide Stamping: Also known as four-way or multi-slide stamping, this technique is the most suitable for making complex components with numerous twists or bends. It uses multiple sliding tools to shape a part through several deformations. The process supports fast production at a low cost.

- Fine Blanking: It is a valuable process to provide smooth edges and high accuracy in the manufactured parts. Usually, a mechanical or hydraulic press is used to clamp the metal sheet, perform the blanking operation, and eject the final piece.

Automation in the Stamping Process

Many industries implement automation techniques to become more cost-effective, efficient, and faster. The industrial engineering process is no different. As more processes become automated, manufacturers use machines to support their production processes. Automation becomes more justified and popular when it helps a manufacturer become more productive with fewer workers. As the industry moves forward, the adoption of more automation is imminent. For instance, sensors in press machines make production more efficient and faster with no chance of human error.

From the metal stamping perspective, automation becomes more widespread throughout different phases. In the next few years, expect to witness massive improvement in engineering and manufacturing automation. Watch this progress and use the power of automation in precision stamping with experts.